What is the Piezoelectric Effect?

Piezoelectric Effect is the ability of certain materials to generate an electric charge in response to applied mechanical stress. The word Piezoelectric is derived from the Greek piezein, which means to squeeze or press, and piezo, which is Greek for “push”.

One of the unique characteristics of the piezoelectric effect is that it is reversible, meaning that materials exhibiting the direct piezoelectric effect (the generation of electricity when stress is applied) also exhibit the converse piezoelectric effect (the generation of stress when an electric field is applied).

When piezoelectric material is placed under mechanical stress, a shifting of the positive and negative charge centers in the material takes place, which then results in an external electrical field. When reversed, an outer electrical field either stretches or compresses the piezoelectric material.

The piezoelectric effect is very useful within many applications that involve the production and detection of sound, generation of high voltages, electronic frequency generation, microbalances, and ultra fine focusing of optical assemblies. It is also the basis of a number of scientific instrumental techniques with atomic resolution, such as scanning probe microscopes (STM, AFM, etc). The piezoelectric effect also has its use in more mundane applications as well, such as acting as the ignition source for cigarette lighters.

The History of the Piezoelectric Effect

The direct piezoelectric effect was first seen in 1880, and was initiated by the brothers Pierre and Jacques Curie. By combining their knowledge of pyroelectricity with their understanding of crystal structures and behavior, the Curie brothers demonstrated the first piezoelectric effect by using crystals of tourmaline, quartz, topaz, cane sugar, and Rochelle salt. Their initial demonstration showed that quartz and Rochelle salt exhibited the most piezoelectricity ability at the time.

Over the next few decades, piezoelectricity remained in the laboratory, something to be experimented on as more work was undertaken to explore the great potential of the piezoelectric effect. The breakout of World War I marked the introduction of the first practical application for piezoelectric devices, which was the sonar device. This initial use of piezoelectricity in sonar created intense international developmental interest in piezoelectric devices. Over the next few decades, new piezoelectric materials and new applications for those materials were explored and developed.

During World War II, research groups in the US, Russia and Japan discovered a new class of man-made materials, called ferroelectrics, which exhibited piezoelectric constants many times higher than natural piezoelectric materials. Although quartz crystals were the first commercially exploited piezoelectric material and still used in sonar detection applications, scientists kept searching for higher performance materials. This intense research resulted in the development of barium titanate and lead zirconate titanate, two materials that had very specific properties suitable for particular applications.

Piezoelectric Materials

There are many materials, both natural and man-made, that exhibit a range of piezoelectric effects. Some naturally piezoelectric occurring materials include Berlinite (structurally identical to quartz), cane sugar, quartz, Rochelle salt, topaz, tourmaline, and bone (dry bone exhibits some piezoelectric properties due to the apatite crystals, and the piezoelectric effect is generally thought to act as a biological force sensor). An example of man-made piezoelectric materials includes barium titanate and lead zirconate titanate.

In recent years, due to the growing environmental concern regarding toxicity in lead-containing devices and the RoHS directive followed within the European Union, there has been a push to develop lead free piezoelectric materials. To date, this initiative to develop new lead-free piezoelectric materials has resulted in a variety of new piezoelectric materials which are more environmentally safe.

Applications Best Suited for the Piezoelectric Effect

Due to the intrinsic characteristics of piezoelectric materials, there are numerous applications

that benefit from their use:

High Voltage and Power Sources

An example of applications in this area is the electric cigarette lighter, where pressing a button causes a spring-loaded hammer to hit a piezoelectric crystal, thereby producing a sufficiently high voltage that electric current flows across a small spark gap, heating and igniting the gas. Most types of gas burners and ranges have a built-in piezo based injection systems.

Sensors

The principle of operation of a piezoelectric sensor is that a physical dimension, transformed into a force, acts on two opposing faces of the sensing element. The detection of pressure variations in the form of sound is the most common sensor application, which is seen in piezoelectric microphones and piezoelectric pickups for electrically amplified guitars. Piezoelectric sensors in particular are used with high frequency sound in ultrasonic transducers for medical imaging and industrial nondestructive testing.

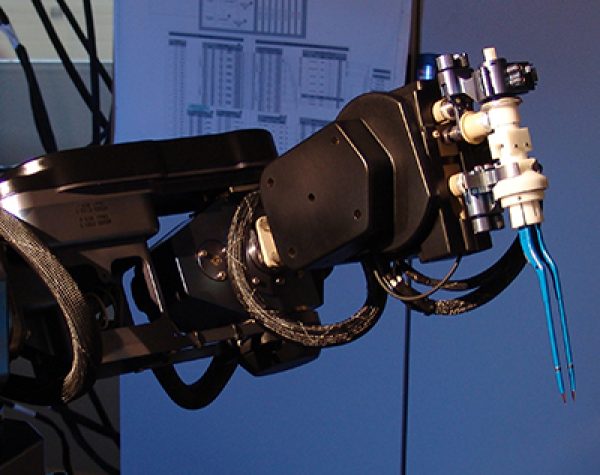

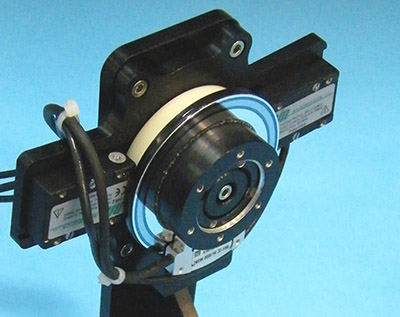

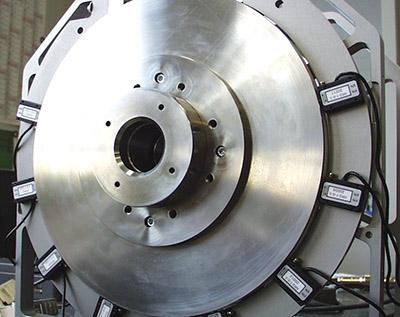

Piezoelectric Motors – The Role of Piezo Crystals in Nanomotion’s Motors

Because very high voltages correspond to only tiny changes in the width of the crystal, this crystal width can be manipulated with better-than-micrometer precision, making piezo crystals an important tool for positioning objects with extreme accuracy, making them perfect for use in motors, such as the various motor series offered by Nanomotion.

Regarding piezo motors, the piezoelectric element receives an electrical pulse, and then applies directional force to an opposing ceramic plate, causing it to move in the desired direction. Motion is generated when the piezoelectric element moves against a static platform (such as ceramic strips).

The characteristics of piezoelectric materials provided the perfect technology upon which Nanomotion developed our various lines of unique piezoelectric motors. Using patented piezoelectric technology, Nanomotion has designed various series of motors ranging in size from a single element (providing 0.4Kg of force) to an eight element motor (providing 3.2Kg of force). Nanomotion motors are capable of driving both linear and rotary stages, and have a wide dynamic range of speed, from several microns per second to 250mm/sec and can easily mount to traditional low friction stages or other devices. The operating characteristics of Nanomotion’s motors provide inherent braking and the ability to eliminate servo dither when in a static position.