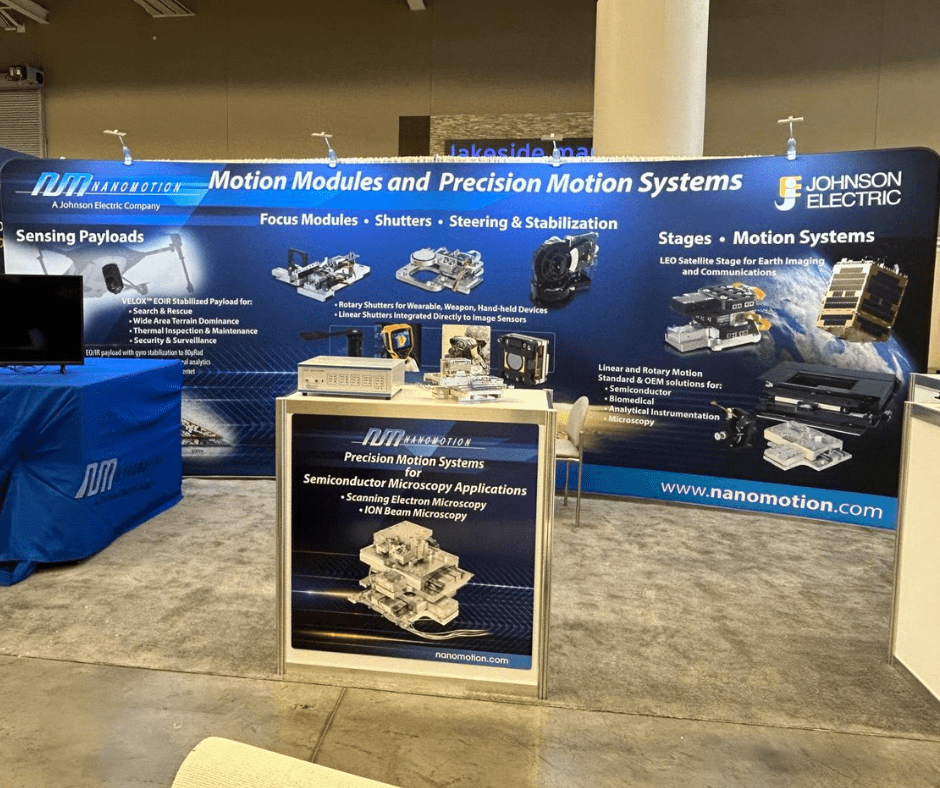

Industry Application

Most motion applications contend with a combination system configuration, operating environment, and key elements of the motion performance, all critical to meeting specific needs. The system design must consider all of the elements at the design level to assure success. While some of the basic elements of motion performance are broadcast in product literature and taken for granted, it is essential to define the necessary characteristics for each application.

From Semiconductor to Biomedial, Photonics to Metrology, the trend to reduce size and increase the overall system performance is a common requirement of motion systems. While configurations may vary, here is a snapshot of a few elements and what can be achieved:

Product Focus

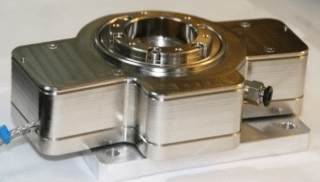

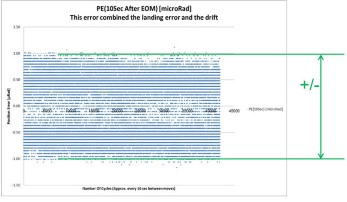

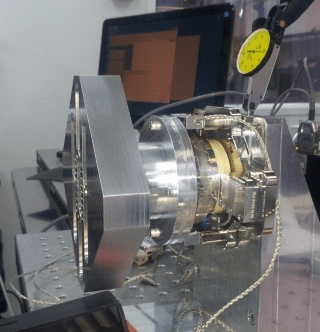

Position Repeatability (FBR060 Rotary Stage)

This graph reflects 45,000 moves of 90° and repeating position to ± 1µrad.

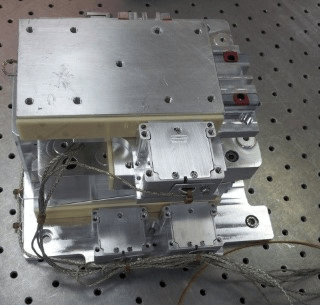

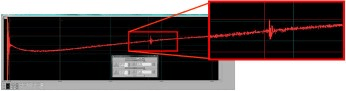

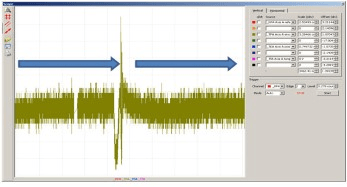

Vibration Suppression (Linear XYZ Assembly)

The plot below represents a shock applied to a linear stage. Within 50ms the system is back in original position. (System fn < 100Hz)

(FBR060 Rotary Stage)

The plot below represents a shock applied to a rotary stage with an eccentric load. Prior to the shock, the stage settled to ±0.2µrad. 20msec after the shock, the stage returned to the same position within ±0.2µrad

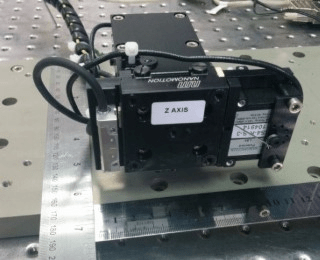

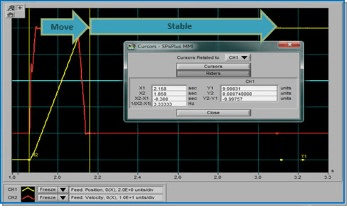

Move & Settle

The plot below represents a move of 10mm in 300msec, with a load of 0.5kg. The vertical axis represents: RED: Reported Velocity (10mm/sec/division) YELLOW: Reported Position (400nm/division)

The selection of a motion system should take into consideration not only what is required, but what can be achieved, as performance requirements will always present new challenges. The ability to demonstrate and document achievable motion performance characteristics is important and must be factored into the design considerations early in the process.

Below represents a comparison of standard stages that are documented verses what is achievable, based on various system designs.

| Performance Characteristics | Standard Nanomotion Stages | Capabilities Developed and Delivered to Customers |

| Range of travel | Up to 500mm | Up to 500mm |

| Drift | <10 nm/min | <1nm/min |

| Landing Accuracy (encoder dependent) | 50 to 300nm | 20nm |

| Linearity | ±30nm | ±1nm |

| Position Repeatability | <3μm | To 1nm |

| Angular Error (Pitch, Yaw, Roll) | 50μRad | 5μRad |

| Straightness / Flatness | <2.5μm/25mm travel | <250nm/25mm travel |

| Damping requirements (Stability) | NA | 3nm @ 50hz |

| Smallest Incremental Move | 20nm | <4nm |

| Velocity | 250mm/sec | 300mm/sec |

| Stiffness | >300HZ | >300HZ |

For a complete understanding of system designs and performance levels, please contact Nanomotion at nano@nanomotion.com or +1 (631)585-3000, or visit www.nanomotion.com.

About

Utilizing proprietary technology, Nanomotion designs and manufactures complete motion solutions from start to finish.

Motion Solutions By Industry